"Outsourcing is the selection of suppliers with expertise in a particular area of business to produce and deliver a component part or service to another company" - Verma & Boyer, 2010.

“Outsourcing is the use of supply chain partners to provide products or services” – Bozarth & Handfield, 2012.

Over the past decade, outsourcing of noncore production and service activities to external suppliers has become a common method of streamlining and improving processes.

The use of outsourcing has increased for two primary reasons:

1. The total quality management movement in the 1980s helped increase companies' awareness that it is difficult to be "world class" in multiple activities and that settling for second-best products produced "in-house" just to maintain the work within a single organization is not the best approach.

2. The rapid increase in the in the capabilities of information technologies and other communication devices has made managing multitier supply chains much easier.

As one can

see in the chart above Nike kept its general positions such as Marketing,

Accounting, Promotion, General Management and Product Development in house.

http://han.hszuyd.nl/han/MarketlineAdvantage/advantage.marketline.com/Product?pid=8E563969-FC1C-4D3A-8EEE-F9D79F81F0C3

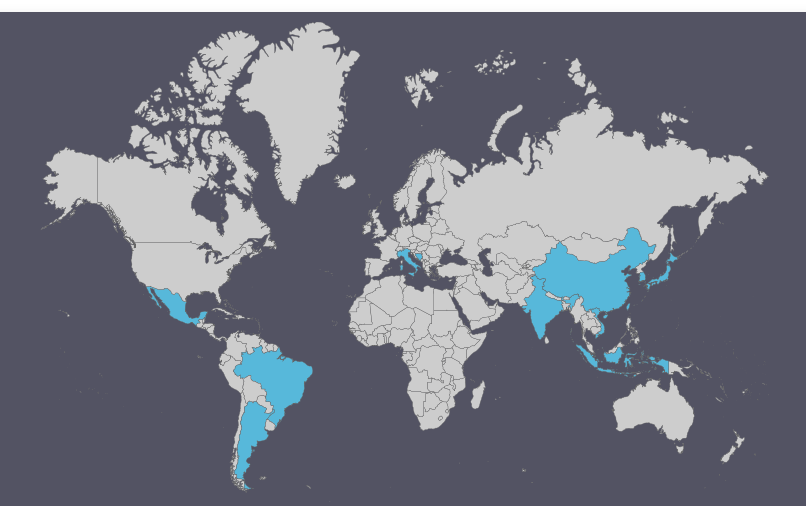

The 12 countries in blue indicate production places for Nike footwear,

which is being outsourced to low labour cost countries.

The countries are:

- Argentina

- Bosnia

- Brazil

- China

- India

- Indonesia

- Italy

- Japan

- Korea

- Mexico

- Taiwan

- Vietnam

Nike. Explanation of how it works in the

organisation and supply chain.

Nike

is not a production company and outsourcers almost all its shoes. Nike’s headquarters

is located in Beaverton, United States, which designs, develops and markets all

the footwear.

Subcontractors

are located in Taiwan and Korea and contract to other Asian countries for

production. Assembly factories that produce the footwear are located in Taiwan,

Korea, China, Indonesia and Vietnam.

The

manufacturing and assembly of their shoes is outsourced to third parties in

Asia. The manufacturers obtain the required raw materials by purchasing them

from suppliers.

Nike

made a conscious decision to retain the design and the marketing of the shoes

because Nike excels at product innovation and marketing of their shoes.

Companies should try to insource processes that are core competencies. These

are usually organizational strengths and abilities, which are developed over a

long period, that customers find valuable and competitors find difficult or

oven impossible to copy (C. Bozarth & B. Handfield, 2012)

After

the product is marketed the shoes will be sold to the customers by the Sporting

goods department and shoe stores, online, catalogue and other retailers, which

are not owned by Nike. The shoes will also be sold by Nike branded stores,

which are owned by Nike. Customers give feedback to Nike and this data will be

used in the development of the new products.

http://www.emeraldinsight.com/journals.htm?articleid=1733216&show=html

Production outsourcing

Advantages

One

of the main advantages that comes with outsourcing production to low labour

cost countries is the low-cost production. Because of this Nike can produce more

efficiently and reduce costs. As a positive consequence of this Nike can lower

the selling prices or increase their profit margins, which gives them a

competitive advantage over their competitors.

By

using an outsourcing strategy Nike has lower investment risk then by using an insourcing

strategy, because they do not have to invest in a production facility, so less

investment is needed up front. This gives them also more strategic flexibility

and access to state-of-the-art products and processes. The market or

technologies could change in the future. In this case it is often easier to

change supply chain partners than internal processes.

Disadvantages

A major disadvantage is

that there is always the possibility of choosing a bad supply chain partner.

The partner might not meet Nike’s expectations on capabilities or quality. If

badly produced shoes are being sold, it will have a bad effect on Nike’s brand

image. Outsourcing can also be bad for the brand image in the case the brand is

related to child labour and sweatshops. Furthermore, when outsourcing

production, Nike’s degree of control and coordination over processes and core

technologies could decrease.

If they would have

insourced their production, they could have increased their degree of control

and ability to oversee the entire production process. Next to that, the

business volume necessary to achieve economies of scale could be achieved more

easily. But a higher investment would be required and their strategic

flexibility could be reduced by this.

Conclusion

Nike outsources the production of the footwear in 12 countries worldwide. They made a conscious decision to retain the design and the marketing of the shoes because Nike excels at product innovation and marketing of their shoes. Even though they got lots of criticism about their outsource activities e.g. child labour in Asia and sweatshops, we think that Nike hugely benefits from its outsource strategy with reduced labour costs as main pinpoint.

Written by:

Ahmed Bairi, 1325157

Jan-Niklas Schmücker, 1325150

Kevin Doutzenberg, 1325152

Paul Erven, 1325142